3D Printed TPU Bellows with PLA Interface Layers

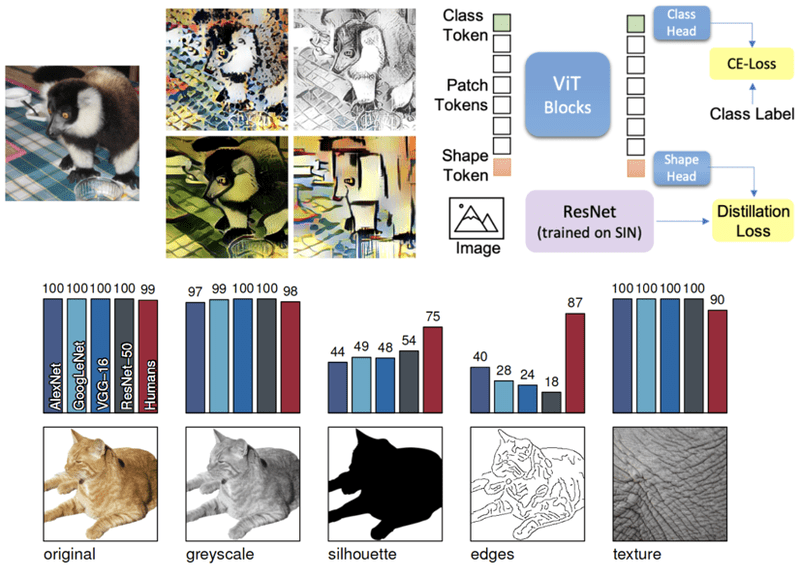

Of all FDM filament types, flexible ones such as TPU invite a whole new way of thinking, as well as applications. Case in point the TPU-based bellows that the [Functional …read more

Of all FDM filament types, flexible ones such as TPU invite a whole new way of thinking, as well as applications. Case in point the TPU-based bellows that the [Functional Part Friday] channel on YouTube recently demonstrated.

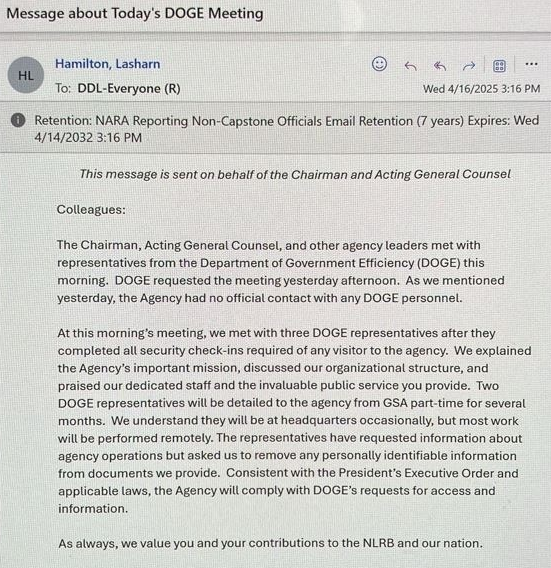

The idea is quite straightforward: you print TPU and PLA in alternating layers, making sure that the TPU is connected to its previous layer in an alternating fashion. After printing, you peel the PLA and TPU apart, remove the PLA layers and presto, you got yourself bellows.

There were some issues along the way, of course. Case in point the differences between TPU from different brands (Sainsmart, Sunlu) that caused some headaches, and most of all the incompatibility between the Bambu Lab AMS and TPU that led to incredibly brittle TPU prints. This required bypassing the feed mechanism in the AMS, which subsequently went down a rabbit hole of preventing the PTFE tube from getting sucked into the AMS. Being able to print TPU & PLA at the same time also requires a printer with two independent extruders like the Bambu Lab H2D used here, as both materials do not mix in any way. Great news for H2D and IDEX printer owners, of course.

As for practical applications for bellows, beyond printing your own 1900s-era camera, accordion or hand air bellows, you can also create lathe way covers and so on.

![Beats Studio Pro Wireless Headphones Now Just $169.95 - Save 51%! [Deal]](https://www.iclarified.com/images/news/97258/97258/97258-640.jpg)

![Honor 400 series officially launching on May 22 as design is revealed [Video]](https://i0.wp.com/9to5google.com/wp-content/uploads/sites/4/2025/05/honor-400-series-announcement-1.png?resize=1200%2C628&quality=82&strip=all&ssl=1)

![[The AI Show Episode 146]: Rise of “AI-First” Companies, AI Job Disruption, GPT-4o Update Gets Rolled Back, How Big Consulting Firms Use AI, and Meta AI App](https://www.marketingaiinstitute.com/hubfs/ep%20146%20cover.png)

![[DEALS] The Premium Python Programming PCEP Certification Prep Bundle (67% off) & Other Deals Up To 98% Off – Offers End Soon!](https://www.javacodegeeks.com/wp-content/uploads/2012/12/jcg-logo.jpg)