5 Ways ERP Software is Revolutionizing the American Manufacturing Industry in 2025

The ERP For American manufacturing industry is undergoing a major transformation in 2025. With rising competition, increasing production costs, and a growing need for efficiency, manufacturers are turning to digital technologies to stay ahead. Among the most impactful tools driving this shift is ERP software. From streamlining operations to enhancing data-driven decision-making, ERP systems are no longer just optional—they are essential. Especially for manufacturers in the USA, ERP solutions are becoming the backbone of efficient, scalable, and compliant operations. In this blog, we’ll explore how ERP software in 2025 is revolutionizing the American manufacturing industry. What is ERP Software? ERP (Enterprise Resource Planning) software is a comprehensive business management tool that integrates core functions such as inventory management, production planning, supply chain operations, accounting, and human resources all into a single unified system. In the context of the manufacturing industry, ERP software provides real-time visibility and control over the entire production lifecycle—from raw material procurement to product delivery. Automating repetitive tasks and centralizing data it helps manufacturers in the USA improve operational efficiency, reduce costs, and make smarter business decisions. In 2025, modern cloud-based ERP systems will be even more powerful, scalable, and tailored to meet the needs of both small and large manufacturing businesses. With built-in analytics, mobile access, and AI-powered insights, ERP software is a key driver of digital transformation in manufacturing. Ways ERP Software is Revolutionizing the American Manufacturing Industry in 2025 1. Streamlining Manufacturing Operations One of the most significant ways ERP software is transforming the American manufacturing industry in 2025 is through streamlining operations. Traditional manufacturing processes often involve disconnected systems, manual tasks, and time-consuming data entry. ERP software eliminates these inefficiencies by automating key functions and unifying processes across departments. With a centralized platform, manufacturers gain real-time visibility into inventory levels, production schedules, and equipment usage. This helps reduce downtime, avoid production delays, and boost overall productivity. Integration with IoT devices and smart sensors also enables automated data collection, improving accuracy and speed. Whether it’s shop floor control, work order tracking, or machine maintenance, ERP software ensures smoother, faster operations, making it an indispensable tool for modern U.S. manufacturers. 2. Optimizing Supply Chain Management A well-optimized supply chain is the backbone of a successful manufacturing business, and in 2025, ERP software is redefining how manufacturers across the USA manage their supply chains. ERP systems offer real-time tracking of raw materials, production progress, and delivery timelines. This visibility allows businesses to better manage procurement, reduce lead times, and prevent stockouts or overstocking. By integrating inventory management, supplier communication, and logistics planning into one platform, ERP software minimizes the risk of delays and disruptions. Advanced features like demand forecasting and automated replenishment further enhance accuracy in planning and purchasing. This not only improves customer satisfaction but also reduces carrying costs and waste, key advantages in today's competitive market. 3. Enabling Data-Driven Decision Making In today’s fast-paced manufacturing world, relying on data is crucial for making informed, timely decisions. ERP software enables manufacturers to centralize their data into a single platform, providing a comprehensive view of operations across the entire organization. With advanced analytics and business intelligence features, ERP systems deliver real-time insights on everything from production efficiency to customer demand. Dashboards and reports give key stakeholders the ability to monitor key performance indicators (KPIs) and make data-backed decisions that drive business growth. Moreover, predictive analytics tools within ERP can help forecast trends, maintenance needs, and potential bottlenecks. This proactive approach enables manufacturers to optimize workflows, minimize downtime, and maintain a competitive edge in the market. 4. Improving Compliance and Quality Control In the U.S., manufacturers must adhere to a variety of stringent regulations, including those set by organizations like the FDA, OSHA, and ISO. Non-compliance can result in costly penalties, product recalls, and damage to brand reputation. This is where ERP software plays a crucial role in ensuring compliance and maintaining high-quality standards. With automated documentation and audit trails, ERP systems allow manufacturers to maintain up-to-date records that are easily accessible d

The ERP For American manufacturing industry is undergoing a major transformation in 2025.

With rising competition, increasing production costs, and a growing need for efficiency, manufacturers are turning to digital technologies to stay ahead. Among the most impactful tools driving this shift is ERP software.

From streamlining operations to enhancing data-driven decision-making, ERP systems are no longer just optional—they are essential. Especially for manufacturers in the USA, ERP solutions are becoming the backbone of efficient, scalable, and compliant operations.

In this blog, we’ll explore how ERP software in 2025 is revolutionizing the American manufacturing industry.

What is ERP Software?

ERP (Enterprise Resource Planning) software is a comprehensive business management tool that integrates core functions such as inventory management, production planning, supply chain operations, accounting, and human resources all into a single unified system.

In the context of the manufacturing industry, ERP software provides real-time visibility and control over the entire production lifecycle—from raw material procurement to product delivery.

Automating repetitive tasks and centralizing data it helps manufacturers in the USA improve operational efficiency, reduce costs, and make smarter business decisions.

In 2025, modern cloud-based ERP systems will be even more powerful, scalable, and tailored to meet the needs of both small and large manufacturing businesses. With built-in analytics, mobile access, and AI-powered insights, ERP software is a key driver of digital transformation in manufacturing.

Ways ERP Software is Revolutionizing the American Manufacturing Industry in 2025

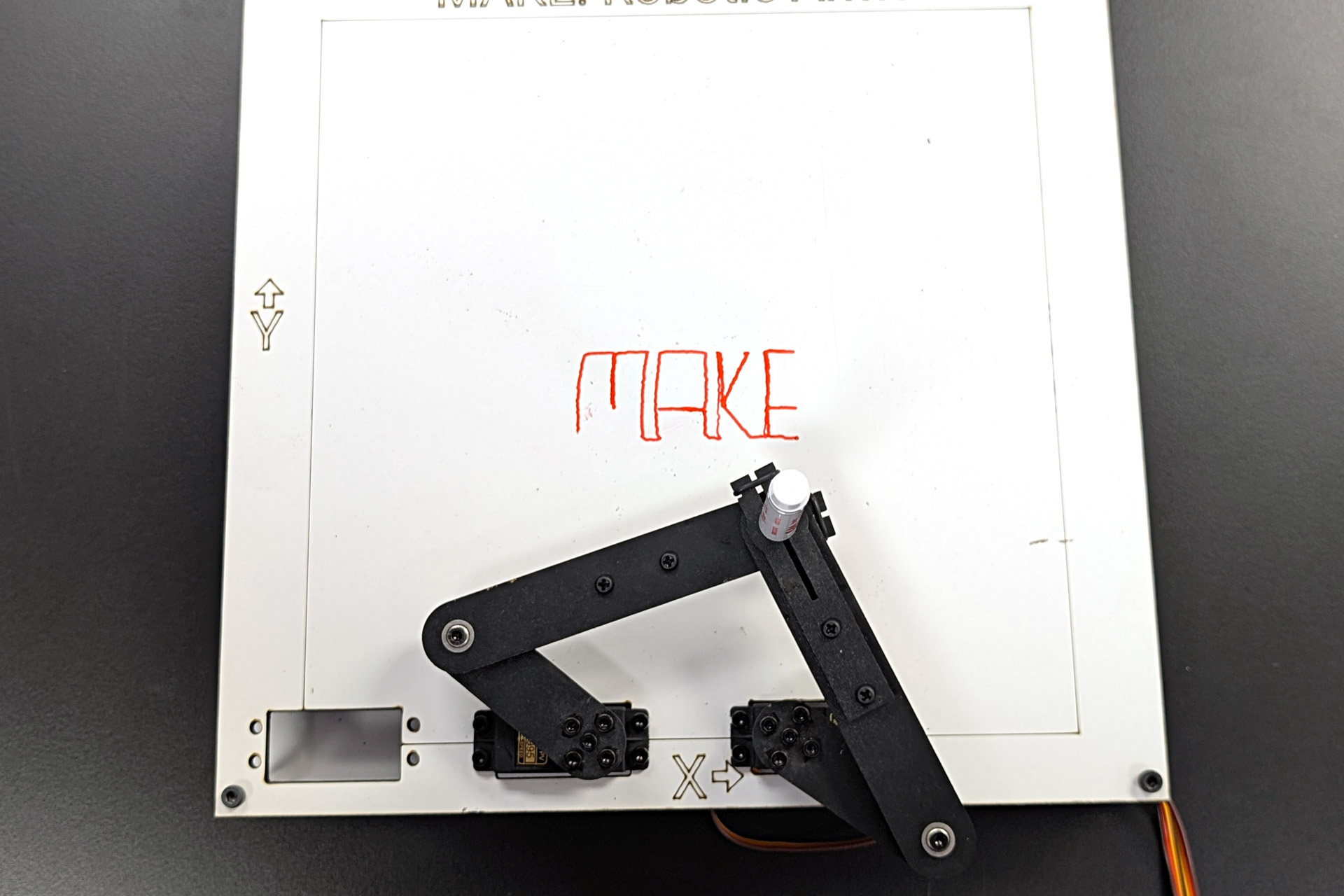

1. Streamlining Manufacturing Operations

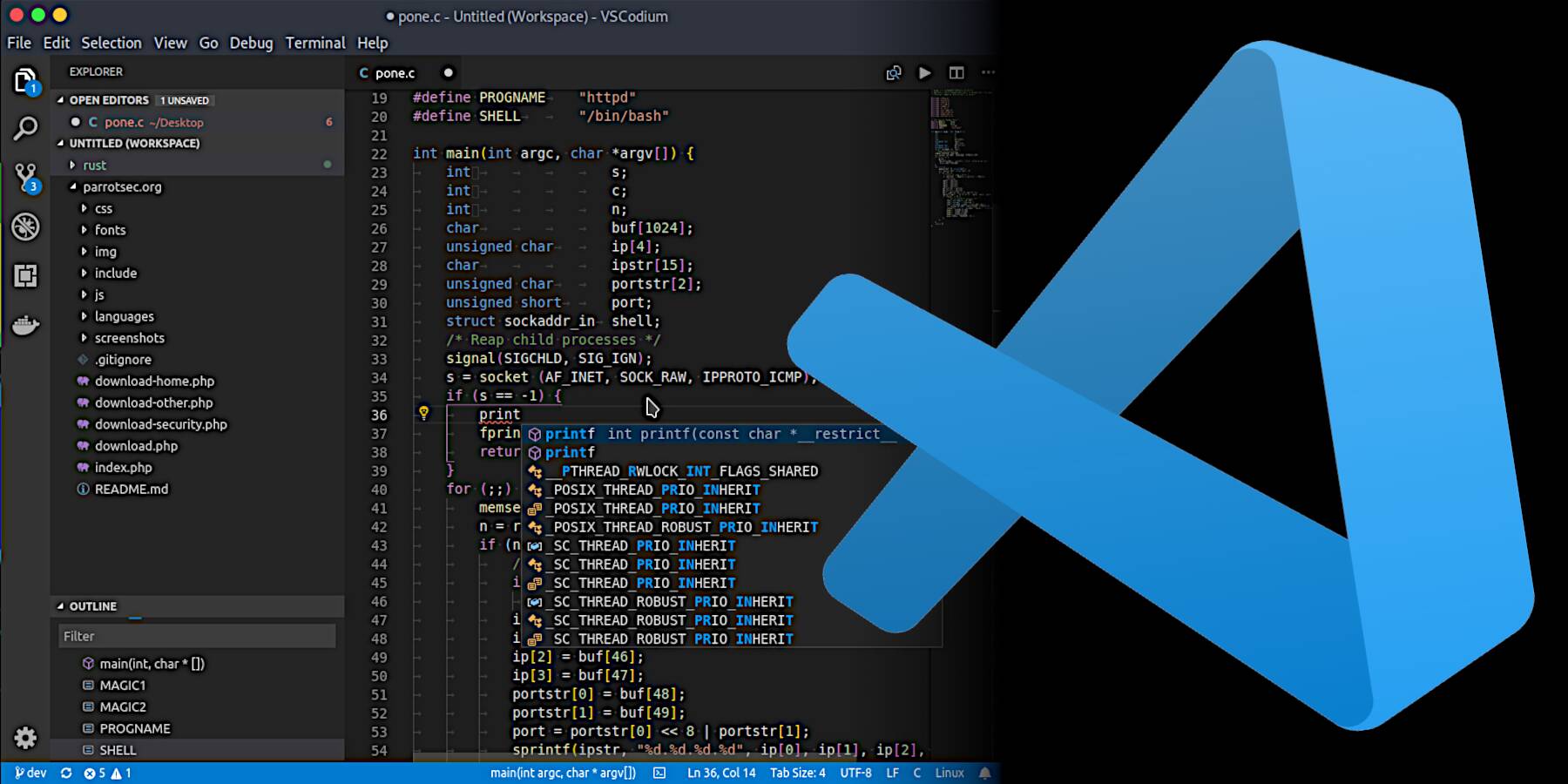

One of the most significant ways ERP software is transforming the American manufacturing industry in 2025 is through streamlining operations. Traditional manufacturing processes often involve disconnected systems, manual tasks, and time-consuming data entry. ERP software eliminates these inefficiencies by automating key functions and unifying processes across departments.

With a centralized platform, manufacturers gain real-time visibility into inventory levels, production schedules, and equipment usage. This helps reduce downtime, avoid production delays, and boost overall productivity. Integration with IoT devices and smart sensors also enables automated data collection, improving accuracy and speed.

Whether it’s shop floor control, work order tracking, or machine maintenance, ERP software ensures smoother, faster operations, making it an indispensable tool for modern U.S. manufacturers.

2. Optimizing Supply Chain Management

A well-optimized supply chain is the backbone of a successful manufacturing business, and in 2025, ERP software is redefining how manufacturers across the USA manage their supply chains.

ERP systems offer real-time tracking of raw materials, production progress, and delivery timelines. This visibility allows businesses to better manage procurement, reduce lead times, and prevent stockouts or overstocking. By integrating inventory management, supplier communication, and logistics planning into one platform, ERP software minimizes the risk of delays and disruptions.

Advanced features like demand forecasting and automated replenishment further enhance accuracy in planning and purchasing. This not only improves customer satisfaction but also reduces carrying costs and waste, key advantages in today's competitive market.

3. Enabling Data-Driven Decision Making

In today’s fast-paced manufacturing world, relying on data is crucial for making informed, timely decisions. ERP software enables manufacturers to centralize their data into a single platform, providing a comprehensive view of operations across the entire organization.

With advanced analytics and business intelligence features, ERP systems deliver real-time insights on everything from production efficiency to customer demand. Dashboards and reports give key stakeholders the ability to monitor key performance indicators (KPIs) and make data-backed decisions that drive business growth.

Moreover, predictive analytics tools within ERP can help forecast trends, maintenance needs, and potential bottlenecks. This proactive approach enables manufacturers to optimize workflows, minimize downtime, and maintain a competitive edge in the market.

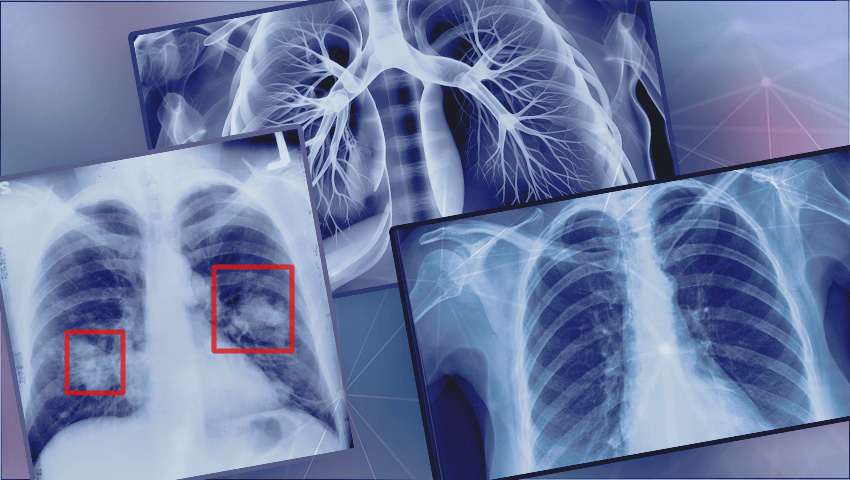

4. Improving Compliance and Quality Control

In the U.S., manufacturers must adhere to a variety of stringent regulations, including those set by organizations like the FDA, OSHA, and ISO. Non-compliance can result in costly penalties, product recalls, and damage to brand reputation. This is where ERP software plays a crucial role in ensuring compliance and maintaining high-quality standards.

With automated documentation and audit trails, ERP systems allow manufacturers to maintain up-to-date records that are easily accessible during audits. This level of traceability ensures that every part of the production process—from raw materials to finished products—meets industry standards.

ERP software also includes features for quality control such as product testing, defect tracking, and real-time reporting, making it easier to spot potential issues before they affect the entire batch. By automating compliance processes and integrating quality management systems, ERP ensures that manufacturers stay compliant and deliver consistently high-quality products.

5. Supporting Scalability and Business Growth

As manufacturers grow, their needs evolve. A key benefit of ERP software is its ability to scale with your business, making it a powerful tool for business growth in 2025 and beyond. Whether you're a small manufacturer or a large enterprise, modern ERP systems are adaptable to your needs.

Cloud-based ERP systems allow for remote access and real-time updates across multiple locations, ensuring consistent operations no matter where your teams are located. This is particularly important for manufacturers expanding across regions or internationally.

The modular architecture of ERP systems means you can add new functionalities as your business grows, such as adding new production lines, expanding your inventory management system, or integrating with additional sales channels. This flexibility ensures your ERP system evolves alongside your business without requiring costly overhauls.

For manufacturers looking to stay competitive, ERP software provides the scalable infrastructure needed to support growth, efficiency, and profitability.

Conclusion

In 2025, ERP software is essential for manufacturers in the USA looking to stay competitive. It streamlines operations, optimizes supply chains, enables data-driven decision-making, and ensures compliance with industry standards.

ERP solutions also provide scalability, making them a key tool for business growth. As the manufacturing sector continues to evolve, adopting ERP software will help businesses improve efficiency, reduce costs, and drive long-term success.

![Apple to Shift Robotics Unit From AI Division to Hardware Engineering [Report]](https://www.iclarified.com/images/news/97128/97128/97128-640.jpg)

![Apple Shares New Ad for iPhone 16: 'Trust Issues' [Video]](https://www.iclarified.com/images/news/97125/97125/97125-640.jpg)

![Hands-on: Motorola’s new trio of Razr phones are beautiful, if familiar vessels for AI [Gallery]](https://i0.wp.com/9to5google.com/wp-content/uploads/sites/4/2025/04/motorola-razr-2025-family-9.jpg?resize=1200%2C628&quality=82&strip=all&ssl=1)

![The big yearly Android upgrade doesn’t matter all that much now [Video]](https://i0.wp.com/9to5google.com/wp-content/uploads/sites/4/2025/04/Android-versions-1.jpg?resize=1200%2C628&quality=82&strip=all&ssl=1)

_NicoElNino_Alamy.png?width=1280&auto=webp&quality=80&disable=upscale#)

![[The AI Show Episode 144]: ChatGPT’s New Memory, Shopify CEO’s Leaked “AI First” Memo, Google Cloud Next Releases, o3 and o4-mini Coming Soon & Llama 4’s Rocky Launch](https://www.marketingaiinstitute.com/hubfs/ep%20144%20cover.png)

![[DEALS] Sterling Stock Picker: Lifetime Subscription (85% off) & Other Deals Up To 98% Off – Offers End Soon!](https://www.javacodegeeks.com/wp-content/uploads/2012/12/jcg-logo.jpg)

.jpg?#)