How Artificial Intelligence Development Services Are Shaping the Future of Smart Manufacturing

The manufacturing industry is undergoing a digital revolution. Traditional factories, once reliant solely on manual labor and fixed workflows, are rapidly evolving into intelligent production units—thanks in large part to artificial intelligence (AI). This transformation, often referred to as Industry 4.0, combines AI with robotics, IoT (Internet of Things), and big data to create responsive, efficient, and automated environments.

The manufacturing industry is undergoing a digital revolution. Traditional factories, once reliant solely on manual labor and fixed workflows, are rapidly evolving into intelligent production units—thanks in large part to artificial intelligence (AI). This transformation, often referred to as Industry 4.0, combines AI with robotics, IoT (Internet of Things), and big data to create responsive, efficient, and automated environments.

At the heart of this evolution lies the critical role of artificial intelligence development services. These services are enabling manufacturers to implement intelligent systems capable of real-time monitoring, predictive maintenance, and autonomous decision-making. From supply chain optimization to quality control, AI is reshaping the foundation of how things are made.

The Industrial Shift Toward Intelligence

Smart manufacturing isn’t just about automation; it’s about intelligent decision-making. Factories are increasingly embedded with sensors, connected devices, and systems that generate massive volumes of data. AI uses this data to optimize everything—from production schedules to energy consumption.

By leveraging advanced machine learning algorithms and real-time analytics, manufacturers are making their operations more agile, sustainable, and profitable.

What Do Artificial Intelligence Development Services Offer Manufacturers?

Artificial intelligence development services provide the expertise, frameworks, and custom solutions needed to deploy AI into industrial environments. These services include:

-

Machine learning model creation for predictive analytics

-

AI-powered robotic process automation (RPA)

-

Computer vision systems for defect detection

-

Digital twin technology for real-time simulations

-

Predictive maintenance algorithms

-

Integration with IoT platforms and MES systems

-

Custom AI dashboards for decision support

By working with specialists in artificial intelligence development services, manufacturing companies can accelerate their digital transformation without compromising safety, compliance, or operational continuity.

Key AI Applications in Smart Manufacturing

1. Predictive Maintenance

One of the most valuable applications of AI in manufacturing is predictive maintenance. AI analyzes data from sensors on machines to detect anomalies or patterns that indicate wear and tear. This allows maintenance to be scheduled before a failure occurs—minimizing downtime and extending equipment life.

Companies using predictive maintenance report up to 40% reduction in maintenance costs and 50% fewer breakdowns.

2. Computer Vision for Quality Inspection

AI-powered cameras can inspect products for defects with more speed and accuracy than the human eye. Computer vision algorithms analyze shape, color, texture, and dimensions to identify inconsistencies in real-time, reducing waste and ensuring high-quality output.

This is particularly valuable in industries like automotive, electronics, and pharmaceuticals where precision is critical.

3. Demand Forecasting and Inventory Management

AI helps manufacturers predict demand trends with precision by analyzing historical sales data, market conditions, and even weather patterns. This ensures raw materials are sourced efficiently and products are produced in line with market needs—reducing surplus and storage costs.

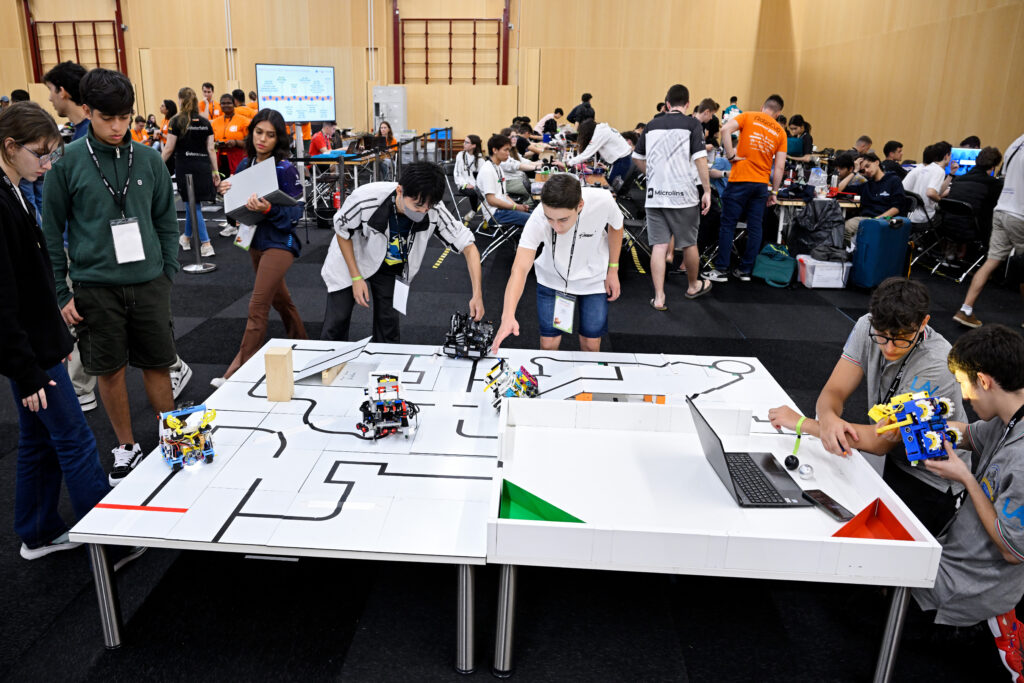

4. Autonomous Mobile Robots (AMRs)

AMRs, guided by AI, are used to transport materials and products across factory floors. These robots can navigate dynamic environments, avoid obstacles, and reroute in real-time—making production workflows more flexible and less labor-intensive.

5. Digital Twins for Real-Time Simulation

A digital twin is a virtual replica of a physical process or machine. AI-enhanced digital twins simulate factory conditions in real time, allowing engineers to test configurations, predict system behavior, and prevent failures—without interrupting actual operations.

Case Study: AI in Automotive Assembly

A leading European automotive manufacturer implemented AI-powered quality control systems to inspect welding points in its assembly line. Within months, defect detection rates improved by 30%, while false positives dropped by half. Maintenance scheduling based on AI predictions further reduced downtime by 20%.

Such outcomes highlight the importance of investing in tailored artificial intelligence development services instead of relying on generic automation tools.

Benefits of AI in the Manufacturing Sector

-

Higher Operational Efficiency

AI systems optimize workflow and reduce manual intervention. -

Cost Reduction

Fewer breakdowns, better energy use, and waste reduction lead to major cost savings. -

Improved Product Quality

Real-time monitoring ensures consistent quality. -

Workplace Safety

AI-powered robots and sensors minimize human exposure to hazardous environments. -

Faster Decision-Making

AI-powered dashboards provide real-time insights, enabling managers to act swiftly.

Implementation Challenges

Despite its benefits, adopting AI in manufacturing comes with hurdles:

1. Data Complexity and Infrastructure

Legacy systems may not generate or handle data at the scale required for AI. Manufacturers must invest in IoT devices and cloud-based platforms to gather and process large datasets.

2. Skilled Workforce Shortage

AI deployment requires data scientists, AI engineers, and technicians who understand industrial systems. Reskilling the existing workforce is crucial.

3. Integration and Compatibility

Merging AI with MES (Manufacturing Execution Systems), ERP, and SCADA platforms can be technically complex. It often requires custom middleware or APIs.

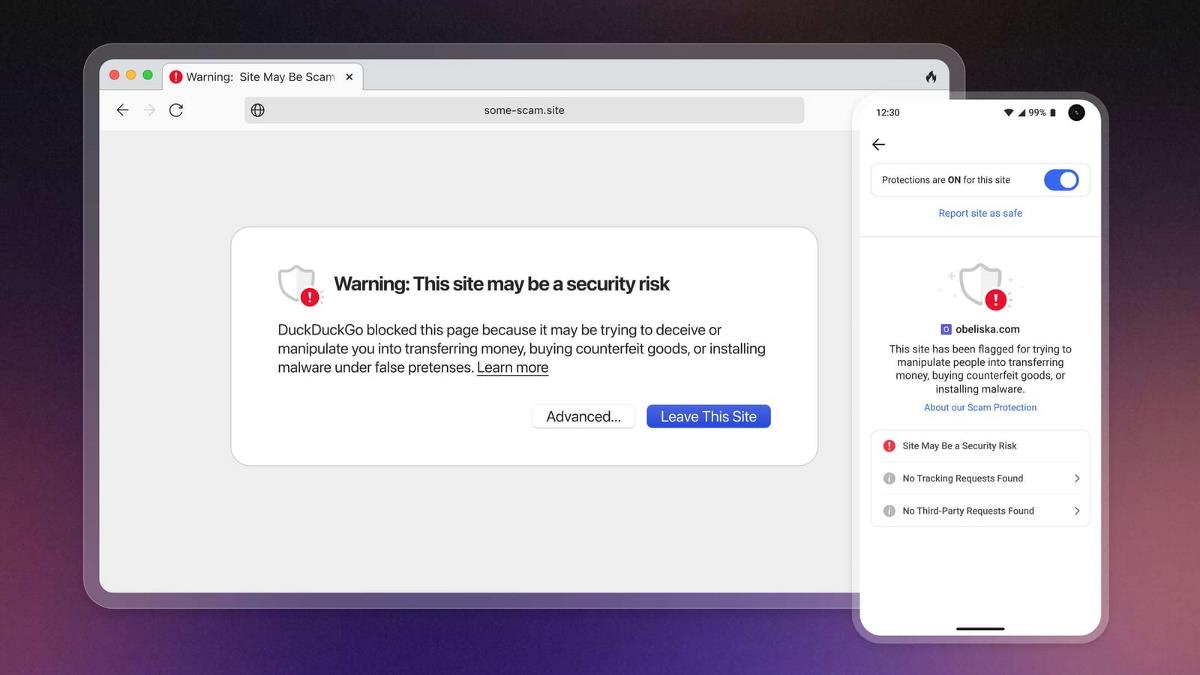

4. Security and IP Concerns

With more devices connected, cybersecurity becomes a major concern. Protecting sensitive data, proprietary designs, and algorithms from threats is essential.

Why Partnering with Experts Matters

Manufacturers that attempt DIY AI deployments often struggle with scalability, performance issues, or misaligned outcomes. Engaging with providers of artificial intelligence development services ensures:

-

Customized AI models for your exact industrial environment

-

Secure and compliant system architectures

-

Ongoing monitoring, retraining, and optimization

-

Compatibility with existing IT/OT infrastructure

Most importantly, expert partners help reduce the risk of downtime or production delays during deployment.

The Future of Smart Manufacturing with AI

The next decade will see even more advanced AI applications in manufacturing, such as:

-

Self-optimizing factories that adjust operations based on real-time conditions

-

Emotion AI in worker safety systems to detect fatigue or stress

-

Generative design tools that create optimal product blueprints

-

Sustainability algorithms that minimize environmental impact

As governments and industries push for greener and smarter manufacturing, AI will remain at the center of this evolution.

Final Thoughts

The rise of AI marks a pivotal moment in manufacturing history. No longer confined to research labs or tech companies, AI has become a practical, scalable tool that manufacturers can—and must—embrace to stay competitive.

From improving product quality to enhancing supply chain responsiveness, the benefits of intelligent automation are both immediate and long-term. But realizing these advantages demands more than just technology—it requires vision, strategy, and expert execution.

That’s where artificial intelligence development services come in. By partnering with the right team, manufacturers can future-proof their operations and lead the next industrial revolution.

![Oakley and Meta Launch Smart Glasses for Athletes With AI, 3K Camera, More [Video]](https://www.iclarified.com/images/news/97665/97665/97665-640.jpg)

![How to Get Your Parents to Buy You a Mac, According to Apple [Video]](https://www.iclarified.com/images/news/97671/97671/97671-640.jpg)

_Paul_Markillie_Alamy.jpg?width=1280&auto=webp&quality=80&disable=upscale#)

_Frank_Peters_Alamy.jpg?width=1280&auto=webp&quality=80&disable=upscale#)

![[The AI Show Episode 154]: AI Answers: The Future of AI Agents at Work, Building an AI Roadmap, Choosing the Right Tools, & Responsible AI Use](https://www.marketingaiinstitute.com/hubfs/ep%20154%20cover.png)

![[The AI Show Episode 153]: OpenAI Releases o3-Pro, Disney Sues Midjourney, Altman: “Gentle Singularity” Is Here, AI and Jobs & News Sites Getting Crushed by AI Search](https://www.marketingaiinstitute.com/hubfs/ep%20153%20cover.png)

.png?#)