Reducing Fugitive Emissions with Stainless Steel Valves

Fugitive emissions can be a problem for any industry, but they are especially problematic in the petrochemical and refining industries. The leaking gas from these industries is composed of many different hydrocarbons such as equipment leaks and gas from the manufacturing process that have been found to cause respiratory problems, heart disease, cancer and other illnesses. What are the Fugitive Emissions? This type of emission is the release of chemicals into the air from unintended sources. These releases can be accidental or deliberate, but they are not always intentional. They sometimes come from leaks in storage tanks, machinery malfunctions, and unintentional venting during normal operations. This has been an issue faced by many manufacturers because it’s costly and detrimental to the environment. They account for about 3% of all man-made global warming since 1850 by releasing methane into the atmosphere. Methane is a particularly potent greenhouse gas, with global warming potential (GWP) more than 25 times that of carbon dioxide over a 100-year period. This makes controlling fugitive emissions a crucial environmental responsibility for industries handling volatile organic compounds (VOCs) and hydrocarbons How to Mitigate this Issue? KDV is looking to reduce emissions by promoting the use of diaphragm valves in place of other types of valves where appropriate. Most people don’t think about valves much. They just turn them on and off when they need to, but do you know how many different types of valves exist? One of the oldest is the Stainless Steel Diaphragm Valve, it’s available on the market and addresses this issue by nature of its design. Diaphragm valves are particularly useful in applications that demand high purity, corrosion resistance, and minimal maintenance, such as pharmaceutical, chemical, and food processing industries.

Fugitive emissions can be a problem for any industry, but they are especially problematic in the petrochemical and refining industries. The leaking gas from these industries is composed of many different hydrocarbons such as equipment leaks and gas from the manufacturing process that have been found to cause respiratory problems, heart disease, cancer and other illnesses.

What are the Fugitive Emissions?

This type of emission is the release of chemicals into the air from unintended sources. These releases can be accidental or deliberate, but they are not always intentional. They sometimes come from leaks in storage tanks, machinery malfunctions, and unintentional venting during normal operations.

This has been an issue faced by many manufacturers because it’s costly and detrimental to the environment. They account for about 3% of all man-made global warming since 1850 by releasing methane into the atmosphere. Methane is a particularly potent greenhouse gas, with global warming potential (GWP) more than 25 times that of carbon dioxide over a 100-year period. This makes controlling fugitive emissions a crucial environmental responsibility for industries handling volatile organic compounds (VOCs) and hydrocarbons

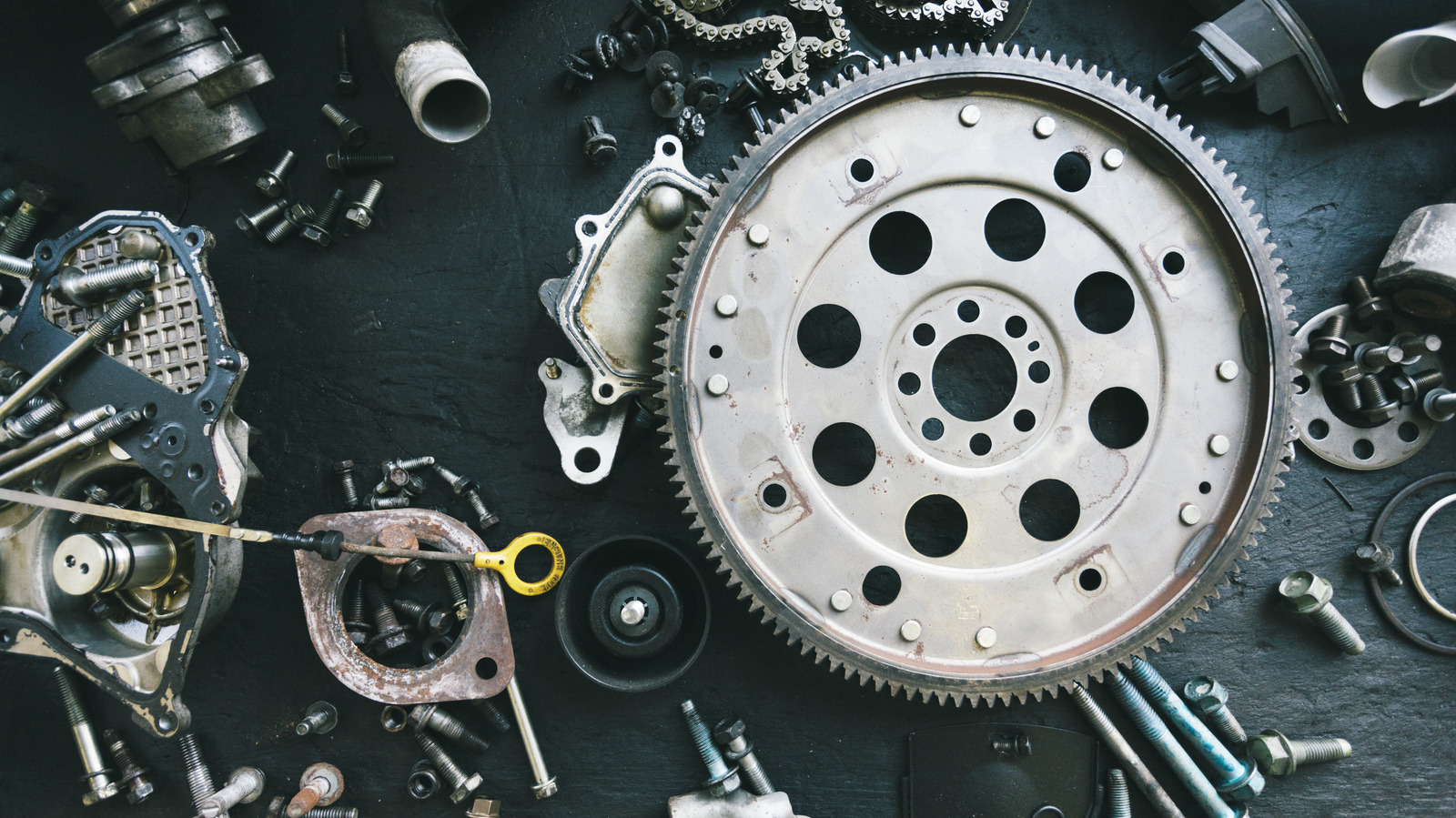

How to Mitigate this Issue?

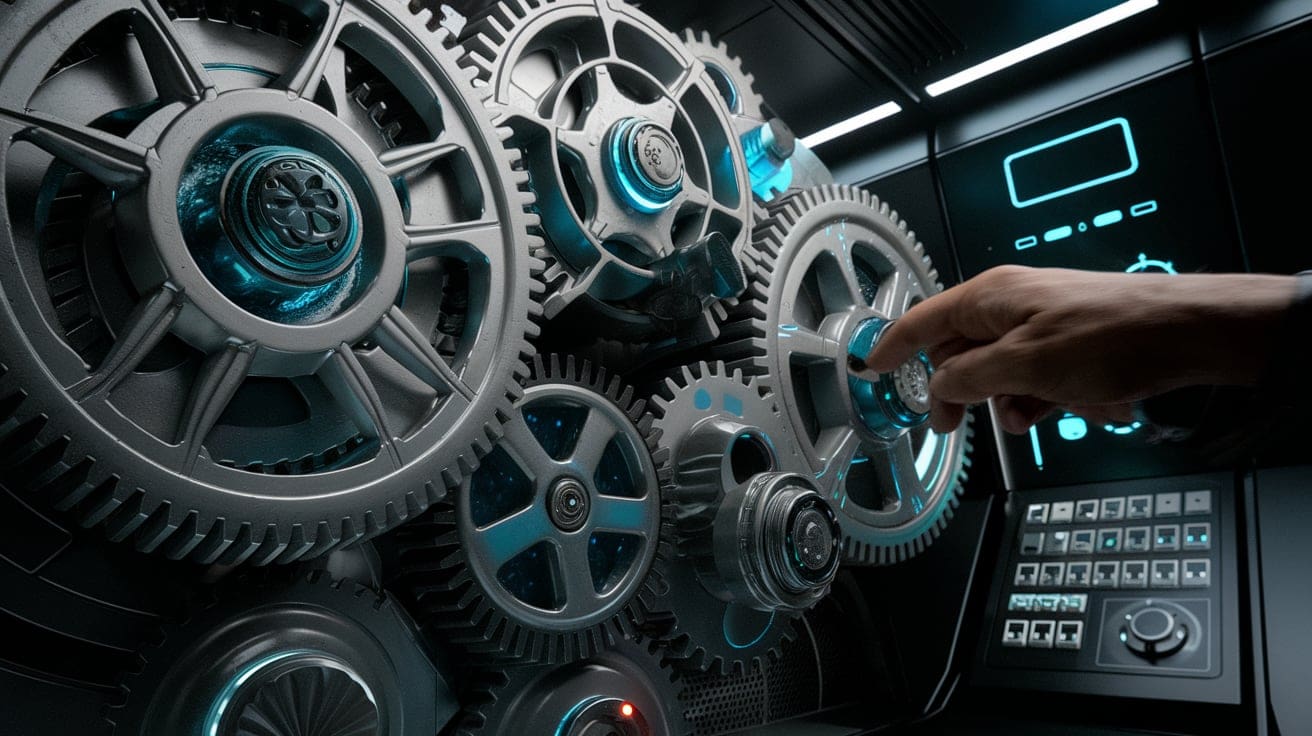

KDV is looking to reduce emissions by promoting the use of diaphragm valves in place of other types of valves where appropriate. Most people don’t think about valves much. They just turn them on and off when they need to, but do you know how many different types of valves exist? One of the oldest is the Stainless Steel Diaphragm Valve, it’s available on the market and addresses this issue by nature of its design. Diaphragm valves are particularly useful in applications that demand high purity, corrosion resistance, and minimal maintenance, such as pharmaceutical, chemical, and food processing industries.

![Security Database Used by Apple Goes Independent After Funding Cut [Updated]](https://images.macrumors.com/t/FWFeAmxnHKf7vkk_MCBh9TcNMVg=/1600x/article-new/2023/05/bug-security-vulnerability-issue-fix-larry.jpg)

![Apple to Split Enterprise and Western Europe Roles as VP Exits [Report]](https://www.iclarified.com/images/news/97032/97032/97032-640.jpg)

![Nanoleaf Announces New Pegboard Desk Dock With Dual-Sided Lighting [Video]](https://www.iclarified.com/images/news/97030/97030/97030-640.jpg)

![Apple's Foldable iPhone May Cost Between $2100 and $2300 [Rumor]](https://www.iclarified.com/images/news/97028/97028/97028-640.jpg)

![One UI 8 leaks again, showing off the tiny list of changes to Samsung’s Android 16 update [Video]](https://i0.wp.com/9to5google.com/wp-content/uploads/sites/4/2024/07/Galaxy-Z-Flip-6-review-photo-2.jpg?resize=1200%2C628&quality=82&strip=all&ssl=1)

-xl-xl.jpg)

.webp?#)

![[The AI Show Episode 144]: ChatGPT’s New Memory, Shopify CEO’s Leaked “AI First” Memo, Google Cloud Next Releases, o3 and o4-mini Coming Soon & Llama 4’s Rocky Launch](https://www.marketingaiinstitute.com/hubfs/ep%20144%20cover.png)