Hire Data Scientists for Smarter Logistics and Supply Chains

Supply chain management has developed from straightforward point-A-to-point-B logistics into sophisticated networks across continents, with thousands of suppliers involved and millions of transactions per day.

The Secret Sophistication of Contemporary Supply Chains

Supply chain management has developed from straightforward point-A-to-point-B logistics into sophisticated networks across continents, with thousands of suppliers involved and millions of transactions per day. Beyond each smooth delivery is an intricate matrix of data moving between systems, partners, and processes that would boggle the minds of even the most experienced data professionals.

Old supply chain systems work in silos, where every function,procurement, inventory management, shipping, and customer service,has its own data stores. That fragmentation means there are blind spots that cost businesses millions in wasted time, inefficiency, and lost opportunities. The answer's not so much better software but better data engineering.

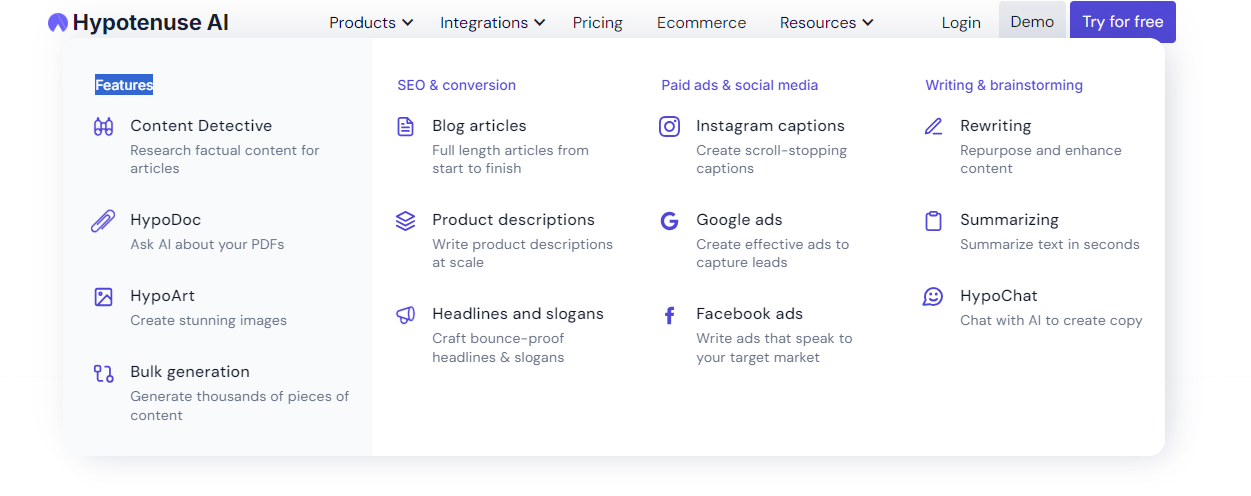

Firms that hire data scientists to optimize supply chains frequently find that their biggest challenge is not creating algorithms,obtaining clean, timely, and complete data to feed the algorithms. Data engineers emerge as the supply chain intelligence architects, building systems capable of capturing, processing, and sharing information throughout the entire logistics system.

Real-Time Visibility: The Data Engineering Challenge

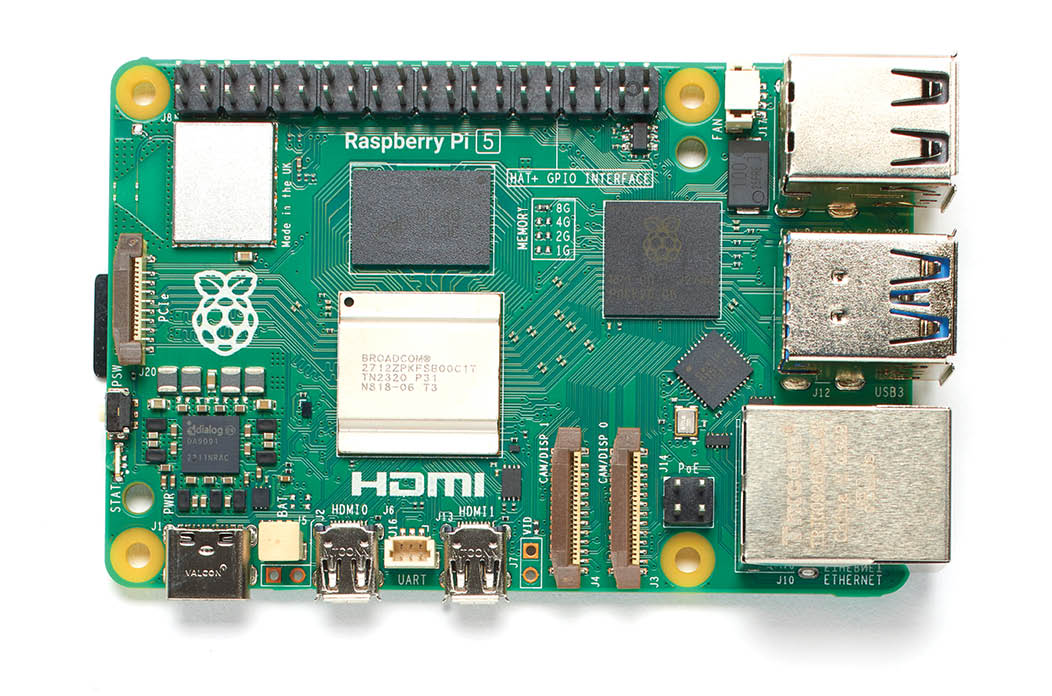

Modern supply chains demand real-time visibility, but achieving this requires sophisticated data engineering solutions. Data must flow seamlessly from IoT sensors in warehouses, GPS trackers on vehicles, RFID systems in stores, and APIs from hundreds of partner systems. Each data source speaks a different language, operates on different schedules, and provides varying levels of reliability.

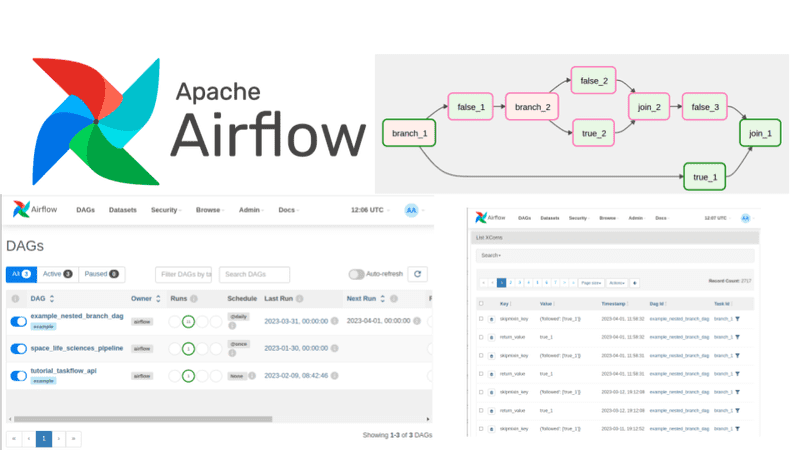

Data engineers confront such difficulties by creating resilient ETL pipelines capable of supporting varied data types, recovering elegantly from system outages, and consistently delivering high-quality data from all sources. They develop streaming architecture that analyzes data in real-time as it comes in instead of processing batch updates, allowing supply chain managers to react to disruptions in minutes instead of hours.

The difficulty is compounded when expanding to global operations. Nations have different data standards, regulatory needs, and technology infrastructures. Data engineers must create systems that will survive in these differences yet provide global consistency and compliance.

Predictive Analytics: Beyond Basic Forecasting

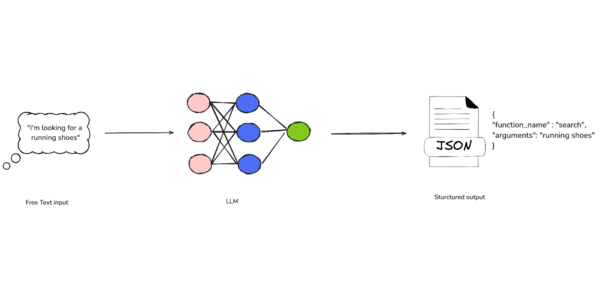

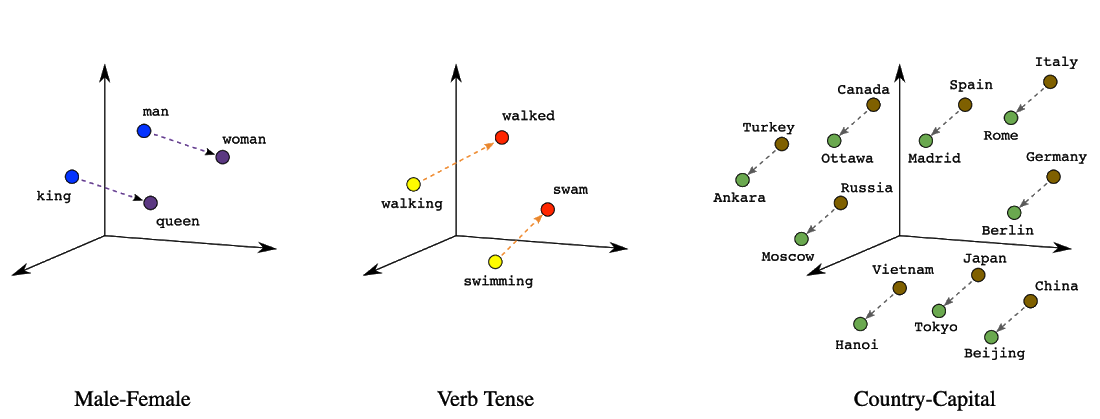

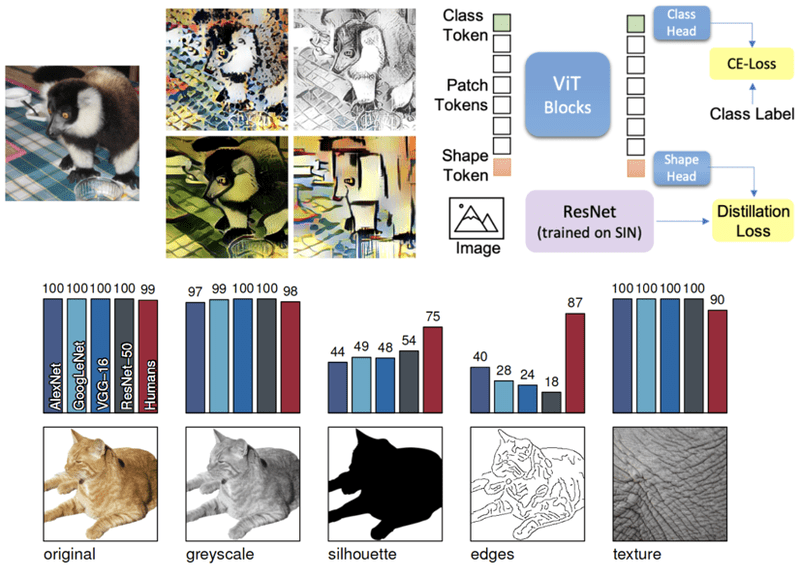

Whereas most companies hire data scientists to develop demand forecasting models, the true value is in end-to-end predictive analytics that take into account several variables at once. Data engineers facilitate that by developing feature stores that merge historical sales data with weather cycles, economic sentiment, social media opinion, and even geopolitical tensions.

These combined datasets enable supply chain algorithms to forecast not only what the customers will purchase, but when suppliers may be disrupted, what transportation corridors will be delayed, and how external influences may affect patterns of demand. The outcome is supply chain management that's proactive instead of reactive.

Data engineers also install feedback loops so that predictive models can learn from real outcomes on an ongoing basis. When predictions diverge from reality, the system automatically corrects its algorithms and modifies subsequent forecasts, generating supply chains that get smarter by the day.

Automation and Intelligent Decision-Making

The grand objective of intelligent supply chains is to have automatic decision-making that is quicker in responding to dynamic conditions than human responders. This mandates data engineers to design systems that are capable of processing information, analyzing alternatives, and initiating action without any manual intervention.

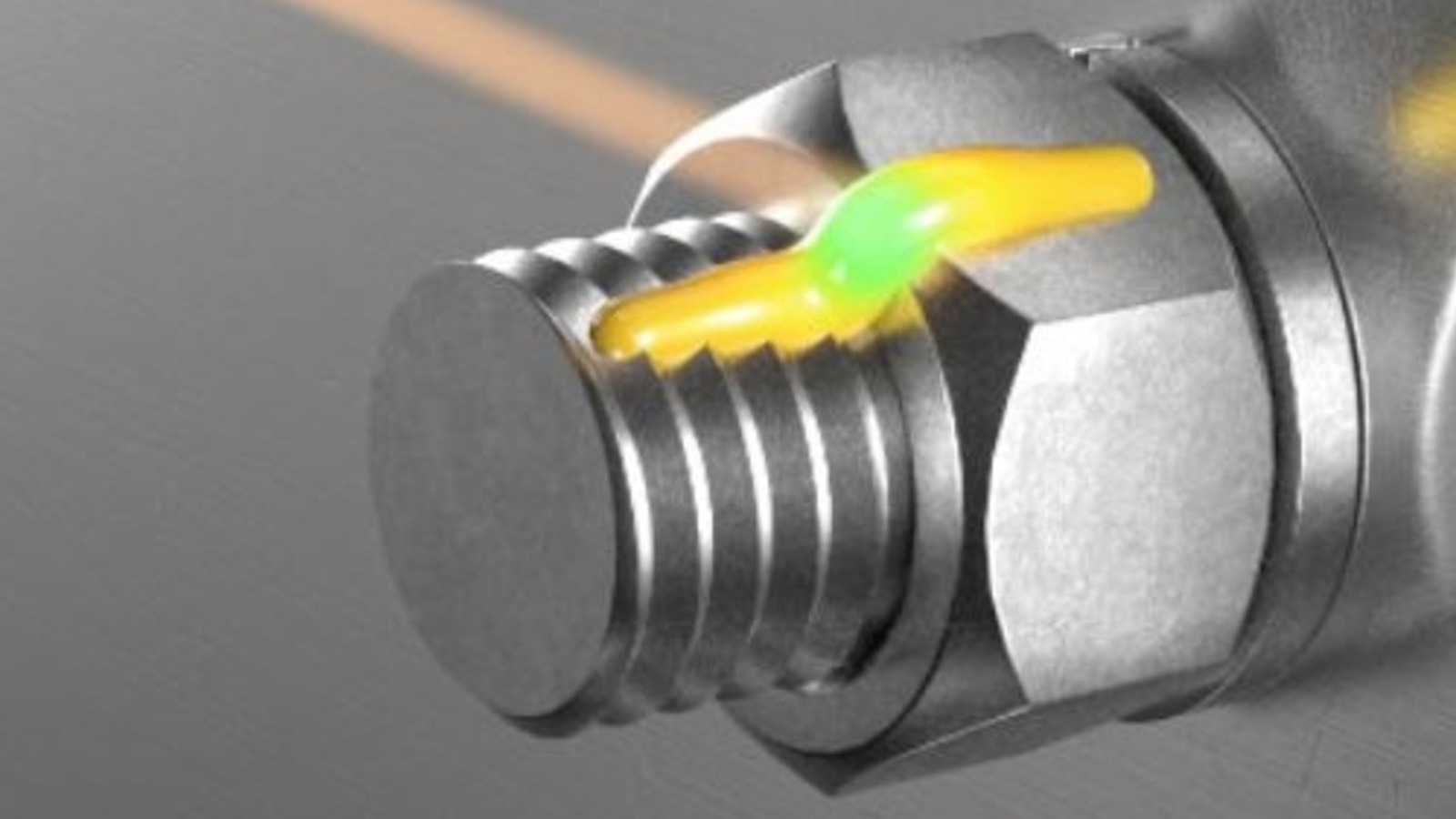

Automated order systems track inventory at multiple locations and place orders automatically when levels fall below optimized levels. Dynamic routing software scans traffic conditions, weather, and delivery urgency to select the best transportation routes in real-time. Smart warehouse management systems integrate robotic systems, human labor, and equipment to optimize efficiency.

These automated systems must have highly dependable data pipelines that are replicated and also have error handling. Data engineers implement monitoring mechanisms that detect anomalies, notify human operators when the need arises, and continue to function as a system despite the failure of individual components.

Integration Across Partners and Platforms

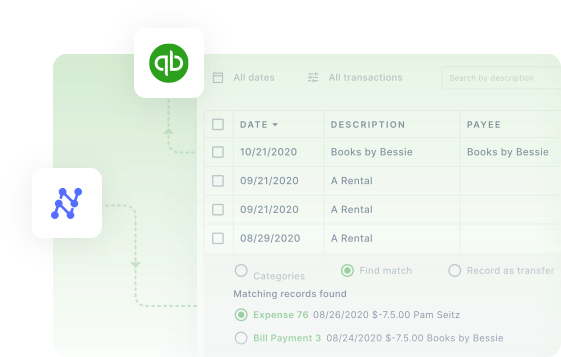

There are multiple organizations with various standards, systems, and priorities in supply chains. Data engineers develop integration platforms which are capable of integrating with partner systems, data formats standardization, and keeping data secure while facilitating collaboration.

API management becomes inevitable when working with hundreds of suppliers, logistics, and retailers. Data engineers deploy systems that are able to manage different API specifications, authentication, and authorization and maintain data consistency across all the connections.

Firms that hire data scientists for supply chain collaborations frequently discover that the technical integration issues are more difficult to tackle than the analytics ones. Data engineers address these issues by developing versatile integration structures that can conform to new partners and evolving needs without necessitating total system rebuilds.

The Competitive Impact

Organizations that possess advanced data engineering capabilities can provide improved customer service, lower costs of operations, and react faster to changes in the market than their rivals. They can ensure delivery times with greater certainty, streamline inventories to minimize costs, and spot opportunities for further improvements in efficiency.

Supply chain benefits build upon one another over time. Improved data results in improved decisions, leading to improved outcomes, which lead to improved data for future decisions. Businesses that invest in supply chain data engineering build competitive advantages that are sustainable and more and more difficult for others to imitate.

Transformative smart logistics powered by sound data engineering turns supply chains into strategic differentiators driving business growth and customer satisfaction, no longer cost centers.

![WWDC 2025 May Disappoint on AI [Gurman]](https://www.iclarified.com/images/news/97473/97473/97473-640.jpg)

![M4 MacBook Air Hits New All-Time Low of $837.19 [Deal]](https://www.iclarified.com/images/news/97480/97480/97480-640.jpg)

![[The AI Show Episode 150]: AI Answers: AI Roadmaps, Which Tools to Use, Making the Case for AI, Training, and Building GPTs](https://www.marketingaiinstitute.com/hubfs/ep%20150%20cover.png)

![[The AI Show Episode 149]: Google I/O, Claude 4, White Collar Jobs Automated in 5 Years, Jony Ive Joins OpenAI, and AI’s Impact on the Environment](https://www.marketingaiinstitute.com/hubfs/ep%20149%20cover.png)

![Z buffer problem in a 2.5D engine similar to monument valley [closed]](https://i.sstatic.net/OlHwug81.jpg)