Aluminum Business Cards Make Viable PCB Stencils

[Mikey Sklar] had a problem—namely, running low on the brass material typically used for making PCB stencils. Thankfully, a replacement material was not hard to find. It turns out you …read more

[Mikey Sklar] had a problem—namely, running low on the brass material typically used for making PCB stencils. Thankfully, a replacement material was not hard to find. It turns out you can use aluminum business card blanks to make viable PCB stencils.

Why business card blanks? They’re cheap, for a start—maybe 15 cents each in quantity. They’re also the right thickness, at just 0.8 mm, and they’re flat, unlike rolled materials that can tend to flip up when you’re trying to spread paste. They’re only good for small PCBs, of course, but for many applications, they’ll do just fine.

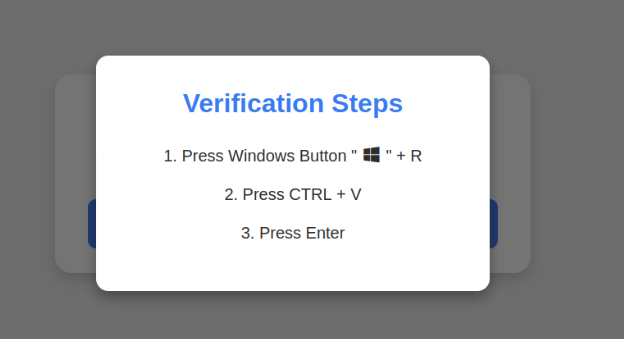

To cut these, you’ll probably want a laser cutter. [Mikey] was duly equipped in that regard already, which helped. Using a 20 watt fiber laser at a power of 80%, he was able to get nice accurate cuts for the stencils. Thanks to the small size of the PCBs in question, the stencils for three PCBs could be crammed on to a single card.

If you’re not happy with your existing PCB stencil material, you might like to try these aluminium blanks on for size. We’ve covered other stenciling topics before, too.

![Apple to Focus on Battery Life and Power Efficiency in Future Premium Devices [Rumor]](https://www.iclarified.com/images/news/96781/96781/96781-640.jpg)

![Apple Reorganizes Executive Team to Rescue Siri [Report]](https://www.iclarified.com/images/news/96777/96777/96777-640.jpg)

_Federico_Caputo_Alamy.jpg?#)

![[The AI Show Episode 139]: The Government Knows AGI Is Coming, Superintelligence Strategy, OpenAI’s $20,000 Per Month Agents & Top 100 Gen AI Apps](https://www.marketingaiinstitute.com/hubfs/ep%20139%20cover-2.png)

![[The AI Show Episode 138]: Introducing GPT-4.5, Claude 3.7 Sonnet, Alexa+, Deep Research Now in ChatGPT Plus & How AI Is Disrupting Writing](https://www.marketingaiinstitute.com/hubfs/ep%20138%20cover.png)

.jpg?width=1920&height=1920&fit=bounds&quality=80&format=jpg&auto=webp#)

.jpg?width=1920&height=1920&fit=bounds&quality=80&format=jpg&auto=webp#)

![Release: Rendering Ranger: R² [Rewind]](https://images-3.gog-statics.com/48a9164e1467b7da3bb4ce148b93c2f92cac99bdaa9f96b00268427e797fc455.jpg)