Supercon 2024: A New World of Full-Color PCBs

Printed circuit boards were once so simple. One or two layers of copper etched on a rectangular fiberglass substrate, with a few holes drilled in key locations so components could …read more

Printed circuit boards were once so simple. One or two layers of copper etched on a rectangular fiberglass substrate, with a few holes drilled in key locations so components could be soldered into place. They were functional objects, nothing more—built only for the sake of the circuit itself.

Fast forward to today, and so much has changed. Boards sprout so many layers, often more than 10, and all kinds of fancy geometric features for purposes both practical and pretty. But what catches they eye more than that, other than rich, saturated color? [Joseph Long] came to the 2024 Hackaday Supercon to educate us on the new world of full color PCBs.

[Joseph] begins his talk with an explanation of terminology. We often look at a PCB and cite its color—say, green for example. As [Joseph] explains, the color comes from the solder mask layer—so called for its job in ensuring solder can only go where it’s supposed to go. The solder mask sits atop the copper layer, but beneath the silk screen which has all the component outlines and part labels.

Solder mask was traditionally green, and this is still the most common color you’ll find in the majority of electronics. However, in recent decades, the available gamut of colors has increased. Now, you can routinely order yellow, blue, purple, and red solder masks quite easily, as well as black or white if you’re so inclined. As some creative makers have found, when designing a board, it’s possible to get several colors into a design even if you’re just using one color of solder mask. That’s because the solder mask appears in slightly different shades when it’s laid over the bare fiberglass of the PCB, versus being laid over copper, for example. Add in white silkscreen and you’ve got quite a lot to work with.

PCB Color Palette

byu/Half_Slab_Conspiracy inPrintedCircuitBoard

Different colors are achievable on a PCB even just by using a single soldermask color.

But what if you want more? What if you want real color? [Joseph] realized this could be possible when he found out that PCB board houses were already using inkjet-like printers to lay down silkscreen layers on small-run boards. Since there was already a printer involved in the board production process, wouldn’t it be simple to start printing on circuit boards in full color?

As it turns out, this was very practical. Two big Shenzhen board houses—JLCPCB and PCBWay—both started delivering color printed boards in 2024. The method involved using a white solder mask layer, with a full-color “silkscreen” layer printed on top using UV-cured ink. Using this ink was a particular key to unlocking full color PCBs. The UV-cured inks are more robust under the tough conditions PCBs face, such as the high temperatures during reflow or hand soldering.

Color printing PCBs might sound trivial and only relevant for cosmetic purposes, but [Joseph] points out it has lots of practical applications too. You can easily color code pinouts and traces right on the the board, a feature that has obvious engineering value. You can even use photorealistic footprints to indicate where other board-level modules should be soldered in, too, making assembly more intuitive. Plus, full color boards are fun—don’t discount that!

As a bonus, we even get to see some of Joseph’s awesome color boards. The graphics are stunning—they really show the potential of full-color PCBs and how they can elevate a project or a fun badge design. If you’re eager to try this out, go ahead and watch [Joseph]’s primer and dive in for yourself!

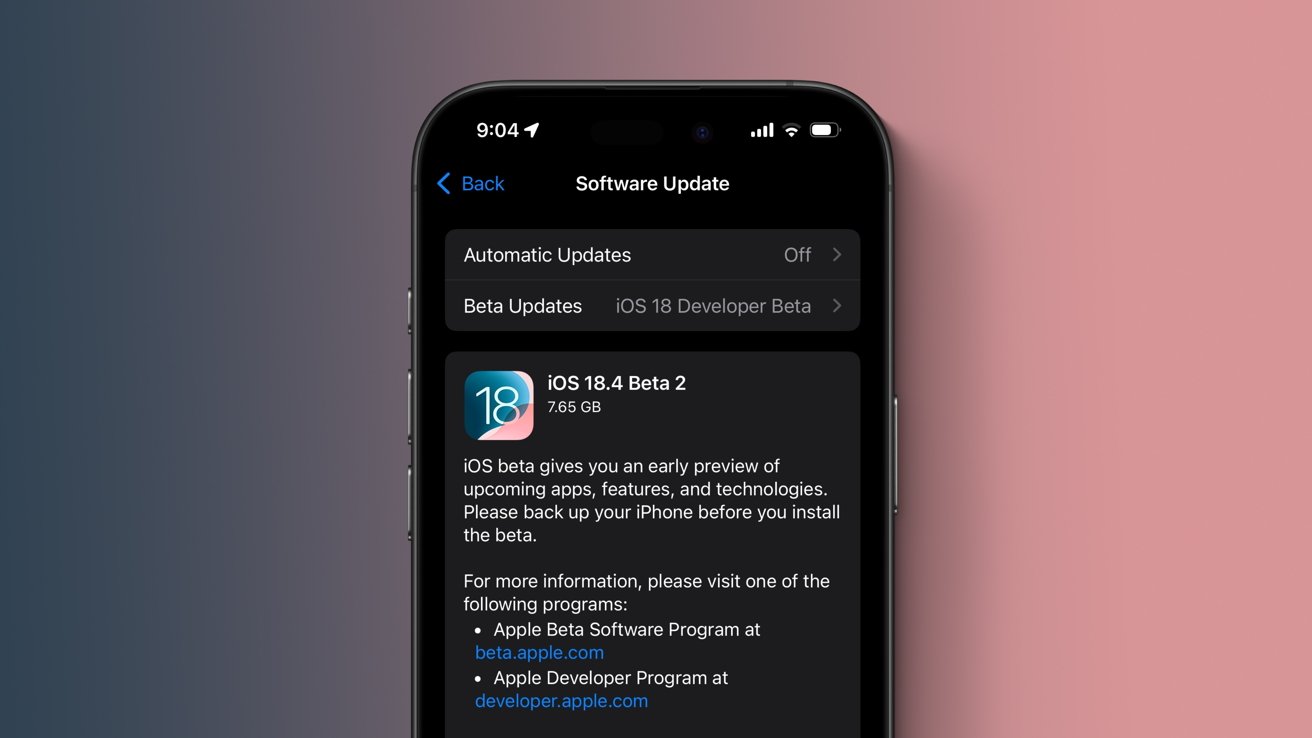

![Lowest Prices Ever: Apple Pencil Pro Just $79.99, USB-C Pencil Only $49.99 [Deal]](https://www.iclarified.com/images/news/96863/96863/96863-640.jpg)

![Apple Releases iOS 18.4 RC 2 and iPadOS 18.4 RC 2 to Developers [Download]](https://www.iclarified.com/images/news/96860/96860/96860-640.jpg)

![[The AI Show Episode 141]: Road to AGI (and Beyond) #1 — The AI Timeline is Accelerating](https://www.marketingaiinstitute.com/hubfs/ep%20141.1.png)

![[The AI Show Episode 140]: New AGI Warnings, OpenAI Suggests Government Policy, Sam Altman Teases Creative Writing Model, Claude Web Search & Apple’s AI Woes](https://www.marketingaiinstitute.com/hubfs/ep%20140%20cover.png)

![[The AI Show Episode 139]: The Government Knows AGI Is Coming, Superintelligence Strategy, OpenAI’s $20,000 Per Month Agents & Top 100 Gen AI Apps](https://www.marketingaiinstitute.com/hubfs/ep%20139%20cover-2.png)

![From broke musician to working dev. How college drop-out Ryan Furrer taught himself to code [Podcast #166]](https://cdn.hashnode.com/res/hashnode/image/upload/v1743189826063/2080cde4-6fc0-46fb-b98d-b3d59841e8c4.png?#)

![[FREE EBOOKS] The Ultimate Linux Shell Scripting Guide, Artificial Intelligence for Cybersecurity & Four More Best Selling Titles](https://www.javacodegeeks.com/wp-content/uploads/2012/12/jcg-logo.jpg)

.jpg?#)

.png?#)

![Mini Review: Rendering Ranger: R2 [Rewind] (Switch) - A Novel Run 'N' Gun/Shooter Hybrid That's Finally Affordable](https://images.nintendolife.com/0e9d68643dde0/large.jpg?#)