How AI Is Quietly Reshaping Logistics: Cutting Waste and Boosting Margins

While finance and healthcare get the headlines for embracing AI, some of the most lucrative use cases are on the roads. Logistics is the backbone of global trade, and executives are catching on—in 2024, 90% of supply chain leaders said technological capabilities are top factors when choosing freight partners. The reason? AI is turning an […] The post How AI Is Quietly Reshaping Logistics: Cutting Waste and Boosting Margins appeared first on Unite.AI.

While finance and healthcare get the headlines for embracing AI, some of the most lucrative use cases are on the roads. Logistics is the backbone of global trade, and executives are catching on—in 2024, 90% of supply chain leaders said technological capabilities are top factors when choosing freight partners. The reason? AI is turning an industry notorious for inefficiency into businesses’ upper hand over the competition.

Historically reliant on paper-based processes, logistics has been a blind spot for supply chain leaders. This lack of visibility fuels the bullwhip effect: small retail demand changes inflate as they travel up the supply chain, reaching raw material suppliers. Coupled with long lead times, this forces each stage—retailers, wholesalers, distributors, and manufacturers—to overorder, exacerbating the problem.

But let’s imagine for a second that instead of filling trucks and warehouses with semiconductor chips only for PC demand to decline, logistics had real-time tracking and supply chain visibility. What if they could predict demand fluctuations with 99.9% accuracy? And provide flexible logistics solutions like on-demand transportation in response?

With AI and machine learning, this ideal might not be as far as business leaders think.

Supply Chain Visibility Explains the Unexplainable

When asked ”Which of freight forwarders’ technological capabilities do you find most valuable?”, 67% of respondents voted for real-time shipment tracking.

Internet of Things (IoT) devices revolutionize cargo tracking, providing granular visibility and real-time alerts about the condition of goods—crucial for time-sensitive or temperature-controlled shipments like food and pharmaceuticals which have strict verification regulations. Not only can supply chain leaders find out how much stock they have and where it is located at any moment, but they can also learn about its condition. Shippers can monitor and share information about whether goods are hot, cold, wet, or dry, and they can see if doors, boxes, or other containers are being opened. These insights explain abnormalities with food items arriving perished, minimizing future waste.

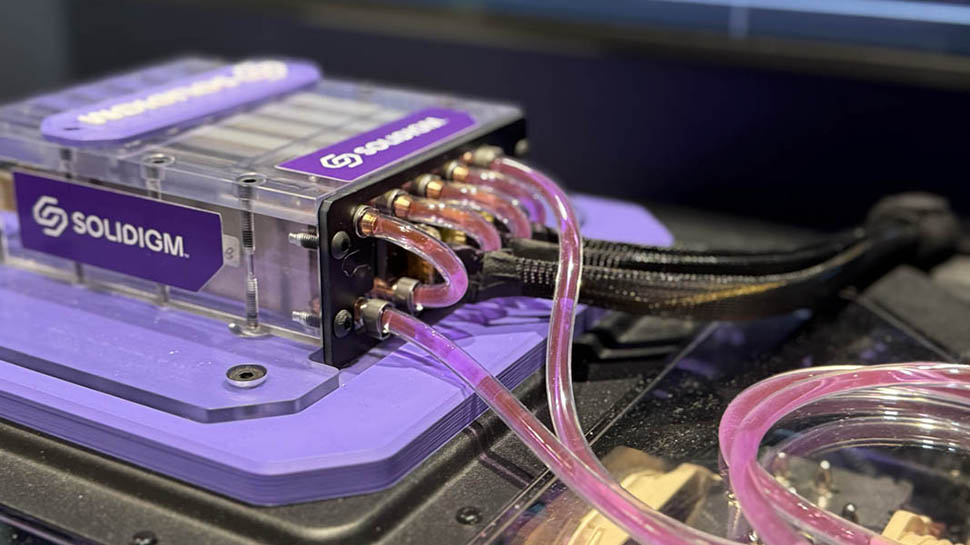

Moving over to the electronics industry, companies can assure customers that products like laptop motherboards are genuine when items are tracked and traced. Warehouse and inventory managers can scan barcodes and QR codes to track stock levels, or use radio frequency identification (RFID) tags attached to objects to trace high-value assets without needing to scan them. More advanced RFID tags offer real-time alerts when conditions (such as temperature) deviate from pre-set thresholds.

Item-level visibility has become a must for shippers and their supply chain partners. Logistics providers must quickly adapt to disruptions and demand changes and this visibility increases resilience. These insights allow businesses to have a holistic view of inventory and make informed decisions in real-time, reducing waste and improving resource utilization.

Demand Forecasting and Reliable Lead Times

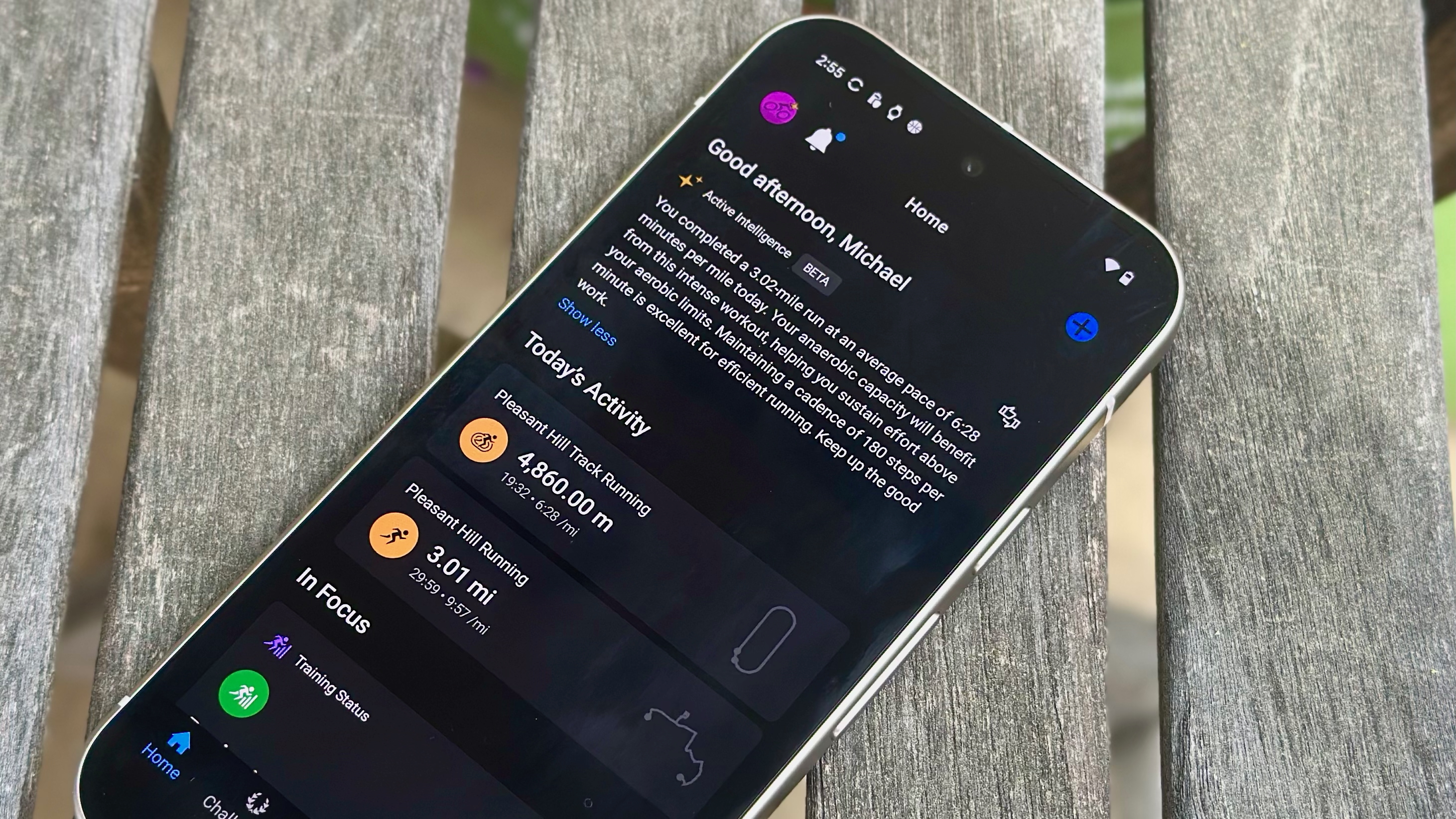

IoT sensors' usefulness extends much further than simply tracking items and updating customers in real time. They provide data that fuels demand forecasting algorithms.

Take Coca-Cola, for example. The soft drink giant leverages IoT to monitor and gather data from its vending machines and refrigerators, tracking real-time metrics for stock levels and consumer preferences analysis. This allows Coca-Cola to make informed predictions about demand for specific product types and flavors.

Freight forwarders increasingly use a similar method to predict freight volume in specific lanes, allowing them to optimize fleet deployment and meet service level agreements (SLAs). Good news for businesses as they benefit from more reliable lead times, which means lower inventory costs and fewer stockouts.

There are two overarching ways logistics companies use forecasting:

- Long-range (strategic): For budgets and asset planning (6-month to 3-year plans).

- Short-range (operational): Most valuable for logistics, predicting ground freight transportation up to 14 days in advance, and 1-12 weeks for ocean shipping.

For example, DPDgroup’s courier company, Speedy, predicts demand by combining historical shipment data (parcel size, delivery times, customer behavior, etc.) with external factors like holidays, retail peaks (Black Friday), etc. Under the new system, AI-powered demand forecasting allowed Speedy to quickly identify and cancel unnecessary trips and line hauls. This led to a 25% hub-to-hub cost reduction and a 14% increase in fleet utilization. McKinsey found similar results in supply chain management, with forecasting tools reducing errors by 20 to 50%.

Load-to-Capacity Matching: Stop Hauling Air

Uber Freight reported in 2023 that between 20% and 35% of the estimated 175 billion miles trucks drive in the US each year are likely empty—draining fuel and labor budgets. Now that AI, ML, and digital twin technology are mainstream, a truck that just made a delivery in Dallas shouldn’t deadhead back to Chicago. AI-driven load-matching platforms analyze freight demand, truck availability, and route patterns to ensure every truck is hauling at maximum efficiency.

Logistics companies take the gathered freight information used in demand forecasting tools (load size, weight, dimensions, type—whether it is perishable, hazardous, etc.) and cross-analyze this with their capacity. AI-powered analytics can review the truck size, features, location, and availability, along with driver hours of service regulations, to connect shippers and carriers in real time. Digital twin technology can potentially take this a step further, simulating virtual scenarios to ensure the optimal match.

Let's say a shipper enters information about their upcoming load into a digital platform. The system analyzes available carrier capacity and matches the load with the most suitable option, considering the optimization factors mentioned earlier. The transaction is processed, and the shipment is tracked throughout its journey.

By tracking assets, predicting demand, and matching loads, logistics companies are saving huge amounts. They are minimizing empty miles, maximizing vehicle utilization, and eliminating carbon footprint—ultimately improving customer relationships with more reliable deliveries.

The benefits extend beyond logistics. This level of supply chain visibility allows retailers and manufacturers to optimize production schedules and reduce inventory holding costs. They can plan shipments more efficiently, minimizing delays and storage fees, and reducing transportation expenses by ensuring optimal truck utilization and minimal wasted capacity.

Any industry dealing with resource allocation—airlines, manufacturing, even cloud computing—can learn from how logistics AI is streamlining operations.

The post How AI Is Quietly Reshaping Logistics: Cutting Waste and Boosting Margins appeared first on Unite.AI.

![Apple's M5 iPad Pro Enters Advanced Testing for 2025 Launch [Gurman]](https://www.iclarified.com/images/news/96865/96865/96865-640.jpg)

![M5 MacBook Pro Set for Late 2025, Major Redesign Waits Until 2026 [Gurman]](https://www.iclarified.com/images/news/96868/96868/96868-640.jpg)

![Apple to Revamp Health App with AI-Powered Doctor [Gurman]](https://www.iclarified.com/images/news/96870/96870/96870-640.jpg)

![Lowest Prices Ever: Apple Pencil Pro Just $79.99, USB-C Pencil Only $49.99 [Deal]](https://www.iclarified.com/images/news/96863/96863/96863-640.jpg)

![What Google Messages features are rolling out [March 2025]](https://i0.wp.com/9to5google.com/wp-content/uploads/sites/4/2023/12/google-messages-name-cover.png?resize=1200%2C628&quality=82&strip=all&ssl=1)

![Chip Glitching 101 with [Hash]](https://hackaday.com/wp-content/uploads/2025/03/glitching.jpeg?#)

![[The AI Show Episode 141]: Road to AGI (and Beyond) #1 — The AI Timeline is Accelerating](https://www.marketingaiinstitute.com/hubfs/ep%20141.1.png)

![[The AI Show Episode 140]: New AGI Warnings, OpenAI Suggests Government Policy, Sam Altman Teases Creative Writing Model, Claude Web Search & Apple’s AI Woes](https://www.marketingaiinstitute.com/hubfs/ep%20140%20cover.png)

![[The AI Show Episode 139]: The Government Knows AGI Is Coming, Superintelligence Strategy, OpenAI’s $20,000 Per Month Agents & Top 100 Gen AI Apps](https://www.marketingaiinstitute.com/hubfs/ep%20139%20cover-2.png)

![From broke musician to working dev. How college drop-out Ryan Furrer taught himself to code [Podcast #166]](https://cdn.hashnode.com/res/hashnode/image/upload/v1743189826063/2080cde4-6fc0-46fb-b98d-b3d59841e8c4.png?#)

![[FREE EBOOKS] The Ultimate Linux Shell Scripting Guide, Artificial Intelligence for Cybersecurity & Four More Best Selling Titles](https://www.javacodegeeks.com/wp-content/uploads/2012/12/jcg-logo.jpg)

.png?#)